Induction coil design has a major impact on process efficiency and final part quality and the best coil design for your product largely depends on your application.

Design and construction of induction furnace.

Many analytical methods could be applied to induction heating and melting problems.

Design and construction of an induction furnace ask latest information abstract report presentation pdf doc ppt design and construction of an induction furnace technology discussion design and construction of an induction furnace paper presentation details.

Certain coil designs tend to work best with specific applications and a less than optimal coil application pairing can result in slow or irregular heating higher defect rates and lower quality products.

Construction of induction furnace there are many different designs for the electric induction furnace but they all center around a basic idea.

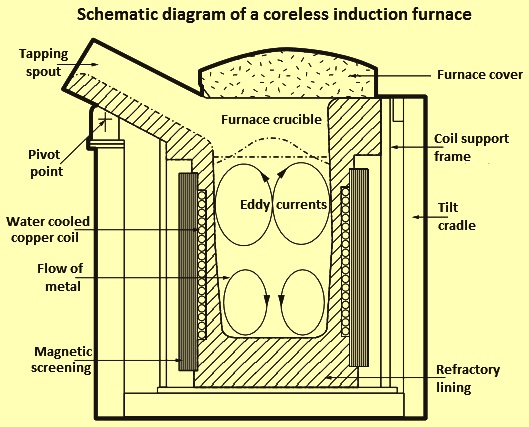

The main task of the present work is to design and construct a coreless induction furnace.

The main task of the present work is to design and construct a coreless induction furnace.

Design and construction of an induction furnace.

Design and construction of the coreless induction furnace dr.

M 7 october 2003 to the department of mechanical engineering in partial fulfilment of the requirements for the degree of ph d.

Many analytical methods could be applied to induction heating and melting problems.

The three foremost requisites for designing and construction of induction furnace are a high frequency electrical power supply a work coil for production of the varying magnetic field and an electrically conductive work piece for heating.

Cooling system submitted by maung thant zin win roll no.

The most suitable.

The electrical coil is placed around or inside of the crucible which holds the metal to be mel.

State of the art of an induction furnace.